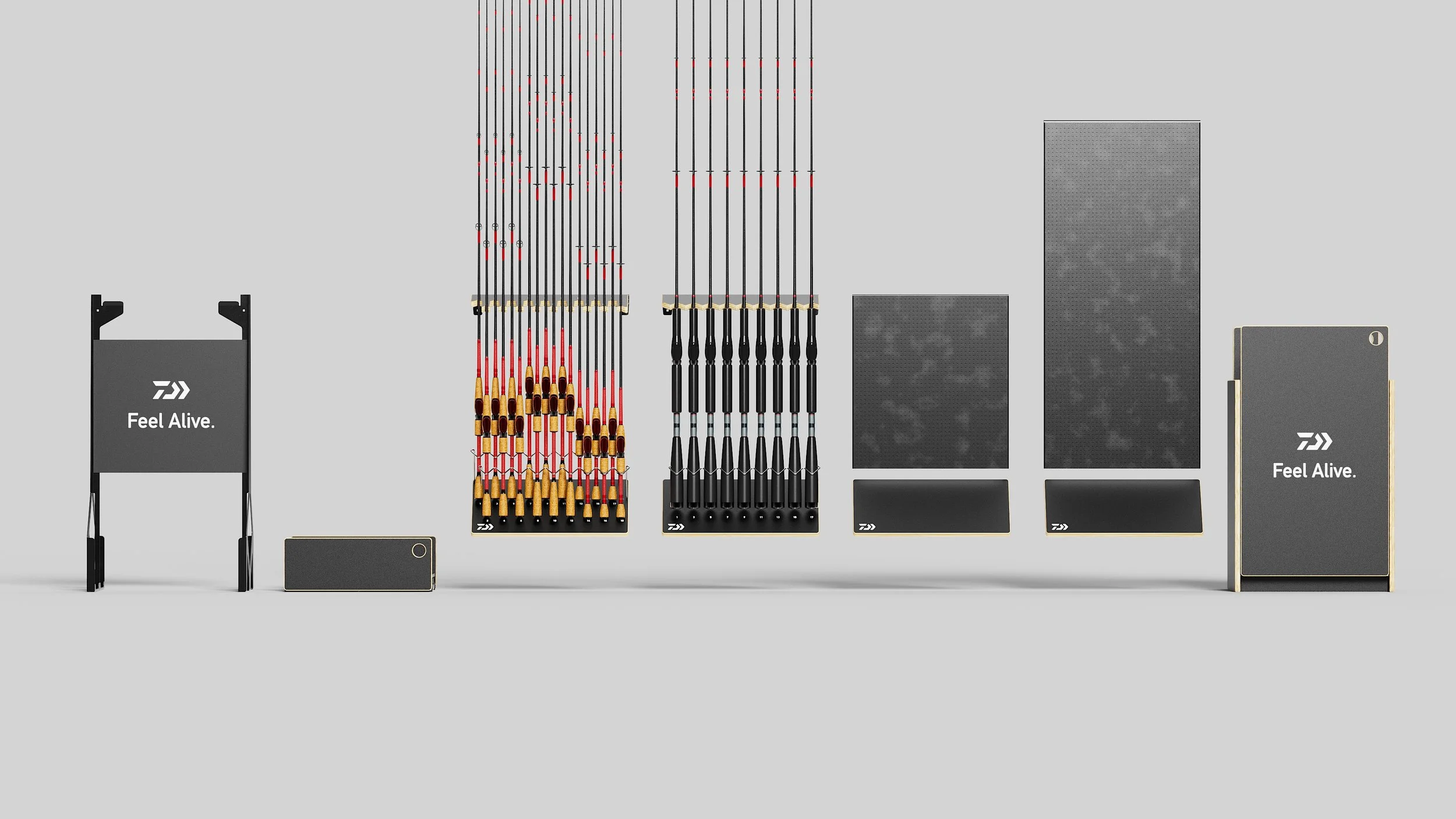

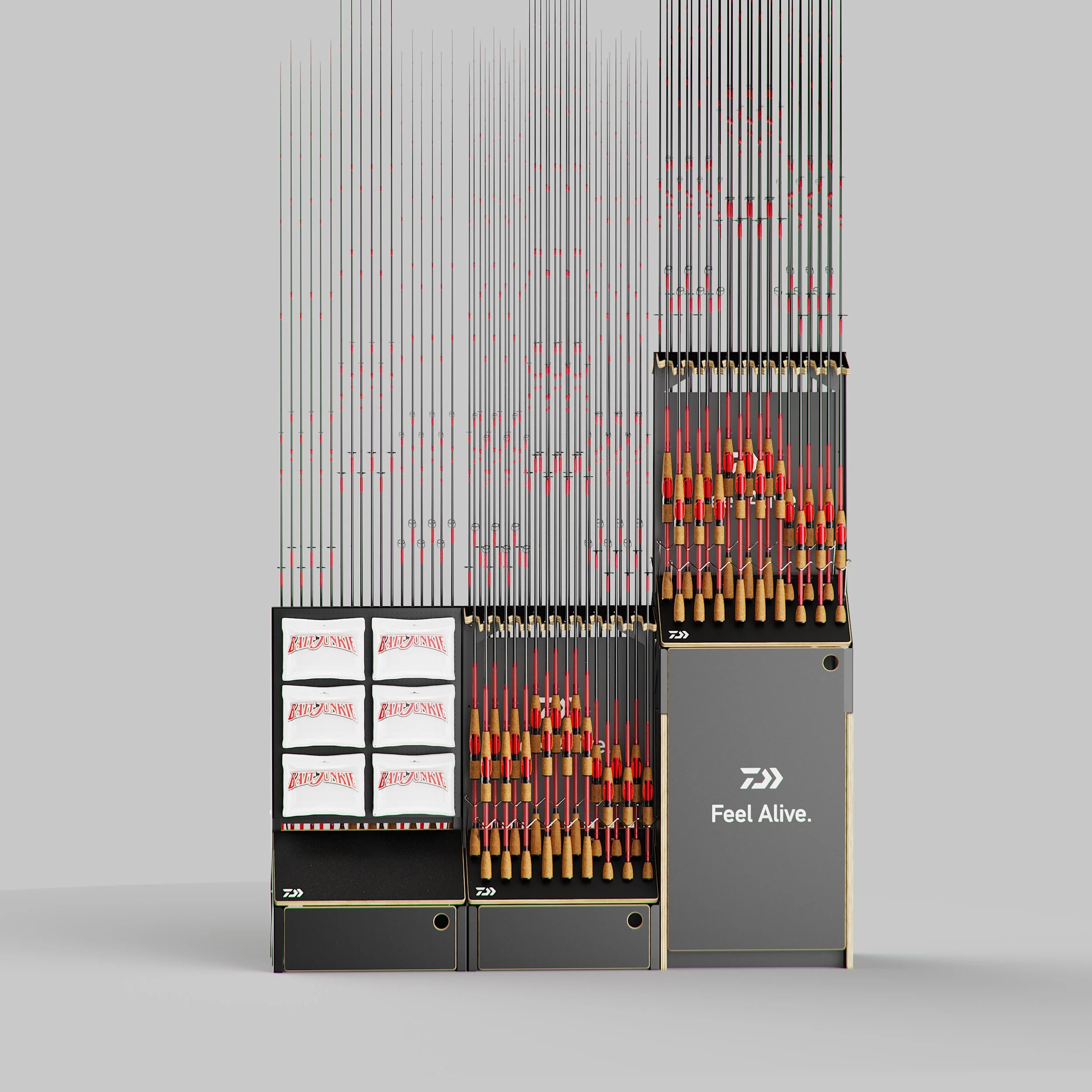

Modular Display Rack

The Brief

Client | Daiwa Australia

Manufacture Technique | Folded Sheet Metal, CNC Bend Wire, CNC Machined Timber

Daiwa Australia approached Deeper Creative to design an in-store fishing rod display system that would not only showcase their range more effectively, but also improve stock density, product visibility, and brand presence across varied retail environments.

21% Cheaper

114% Capacity

∞ More Adaptable

Key Challenges

More stock in store, not more clutter

Simple manufacture, simple assembly

On brand aesthetic and must look great day 1, 100 and 1000

One solution to suit every rod

Flexible branding options

Our Process

1. Resarch & Insights

We started by going deeper (ha!) - Store visits, chats with staff, and a sweep of competitor setups showed the usual pain points:

Floor space wasted by inconsistent rack sizes

Branding obscured by stock, or dated and permanently fixed

Stock getting damaged by poor design and incompatibility with certain rod types

We also drew from adjacent categories like rifle and guitar displays, spotting opportunities for height adjustability, modular back panels, and integrated peripheral displays.

2. Concept Development

With the problems clear, we opened the tap on ideas. Early on we prefer pens over polygons (okay, NURBS). Fast sketches and low-fi visuals let us explore wild directions, communicate intent quickly, and get alignment without over-investing in 3D too soon. It’s our cornerstone philosophy;

“fail fast, fail cheap”

where good ideas rise and weak ones get binned before they cost time and money.

From that wide pass, we move into a convergent approach, refining how the modular system comes together, shaping the aesthetic, and de-risking problem areas before we get into CAD. Throughout, we build in client feedback loops to confirm we’re still on brief and on budget. Once the concept set is approved, we proceed.

3. Concept Validation

Before heavy CAD, we built an off-the-shelf modular mock-up to prove the direction in the real world. It let us adjust angles, heights, and spacing in minutes, run quick user walk-throughs, and lock the key dimensional rules that drive sightlines and access.

That same rig became a simple framework for plug-in, small-scale tests using 3D-printed components, so we could tune contact surfaces and spacing with real rods long before a full prototype.

4. Detail Design

We translated the approved direction into production-ready 3D models for prototyping and vendor assessment, with sensible tolerances, materials, and a clear assembly strategy. The same geometry doubled for renders and stakeholder sign-off, so everyone agreed on exactly what would be built.

We drew on our mass-manufacture experience to make cost-efficient choices without losing the look and feel.

Our manufacutring strategy focused on engineering around widely available processes and finishes so early runs don’t depend on heavy custom tooling, keeping upfront costs down. As volumes scale, the design can leverage tooling to drive unit cost efficiencies. By using common manufacturing techniques, more vendors can quote competitively and production can be multi-sourced without redesign.

5. Vendor Sourcing & Cost Modelling

In parallel, we handled supplier outreach and pricing. We gathered preliminary quotations, worked through DFM feedback, and produced volume-ready samples with clear pricing ladders and inclusions for procurement. The goal was a straight line from approved design to scalable production with no surprises.

What we delivered

A modular display system

Configurable for aisles or walls with swappable modules, including pegboard options for accessories and campaign collateral. Flat-pack, lightweight structure so stores can adapt layouts without redesign.114% More Stock

Increased capacity from 84 rods/m² to 180 rods/m² on a compact footprint, keeping grab-and-replace simple.21% Cheaper

Achieved an approx. 21% reduction in unit cost at comparable volumes, with a tooling-light path that scales efficiently.Adjustable, campaign-ready branding

Interchangeable panels and clear brand zones that stay visible around tall rods, making seasonal messages and range launches easy to roll out.Integrated storage where it helps

A low-profile sliding drawer to tidy rod socks and peripherals, reducing visual clutter and speeding restock.